Process Technicians/ Maintenance Technicians assemble machinery and performs maintenance work on equipment and facilities. They perform repairs to ensure downtime is minimised.

Process Technician/Maintenance Technician Job Description

- Install new production equipment, ensuring it is correctly integrated into existing systems and fully operational.

- Perform routine checks and maintenance on machinery, replacing worn-out parts with new ones.

- Suggest improvements to maintenance processes by analysing current methodologies and identifying opportunities.

- Ensure safety regulations and cleanliness standards are met to maintain a hygienic, safe working environment.

- Set up equipment, ensuring they are ready to operate at peak efficiency from the start of each shift.

- Make minor repairs to the ceiling, walls, and floors of the cleanroom when necessary.

Note

Process Technicians must be very wary of glass fragments in food manufacturing factories. Glass light tubes are covered with acrylic sheets in the event they break. It is to prevent glass fragments from falling into the product.

What you should know about Process Technician/Maintenance Technician jobs in Singapore

Nature of Work

You will work in a clean room to prevent contamination of food products by overseeing machinery operations and ensuring optimal performance.Key Advice

Machinery inspections must be done regularly and thoroughly by replacing worn-out parts quickly to avoid possible contamination of the food products.-

Entry RequirementsEntry Requirements

- A minimum Nitec or Higher Nitec in applied Food Science, Food Technology, Mechanical Engineering, Electrical Engineering, or related fields that provide foundational knowledge relevant to Food Processing and Maintenance.

- Certifications specific to Food Safety (e.g. HACCP for Food Safety Course Level 2) can greatly enhance a candidate's appeal to employers in the Food industry.

-

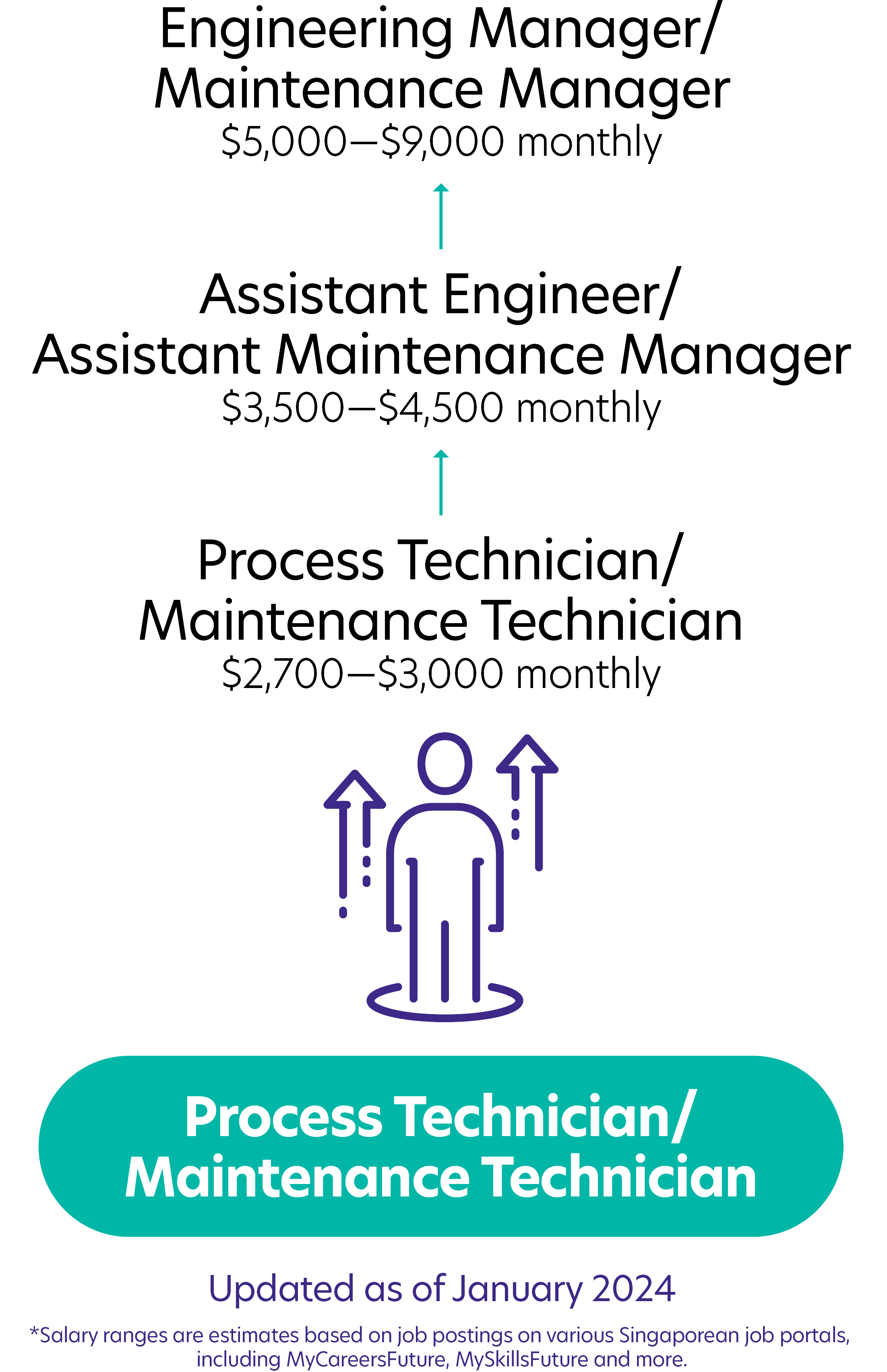

Possible PathwayPossible Pathway

Skills you need to pursue a Process Technician/Maintenance Technician career in Singapore

Hard Skills

Hard Skills

Knowledge of Workplace Safety and Health (WSH) practices

To identify potential hazards and implement safety protocols.Knowledge of Food Sanitation Regulations

Compliance with health standards and the prevention of contamination.Equipment Maintenance

Routine checks and repairs of machinery, ensuring optimal performance and longevity of the equipment.Problem-Solving

Quickly identify and rectify issues that arise, minimising downtime and maintaining productivity.Communication

Convey information, coordinate with team members and ensure a clear understanding of technical procedures.Attention to Detail

Ensure that all aspects of production meet the required standards and specifications.Related Job Roles

Explore Other Programmes

Browse AllYou have bookmarked your first item!

Find it in My Discoveries with insights on your interests!