Incoming Quality Coordinators prepare reports for management, review cargo and conduct quality control checks which include rejecting goods that do not meet the required standards and specifications.

Incoming Quality Coordinator Job Description

- Conduct checks according to internal Standard Operating Procedures (SOPs), government regulatory requirements and legislation to identify non-compliance.

- Conduct product and process audits in accordance with internal audit requirements.

- Conduct basic risk assessments, such as safety and health risk assessments.

- Handle customs clearance processing and inspect cargo acceptance documentation.

- Verify cargo against freight forwarding documents, documenting discrepancies in quantity and quality.

- Inspect materials received to ensure that they conform to standards.

- Inspect the performance of incident or crisis management initiatives.

Note

Every item you own has undergone quality checks conducted by an Incoming Quality Coordinator! He/she ensures that products meet quality standards and are safe for consumers to use.

What you should know about Incoming Quality Coordinator jobs in Singapore

Nature of Work

Expect to oversee Quality Assurance processes, conduct audits and analyse data to ensure compliance with standards.Key Advice

As Incoming Quality Coordinators, you prioritise attention to detail as it's key to maintaining quality standards in every inspection.-

Entry RequirementsEntry Requirements

- Minimally, you should have a GCE 'O' Level qualification to qualify for this job role.

- A diploma or undergraduate degree in Operations or Logistics Management is preferred.

- Certification or training in Quality Management Systems (e.g., ISO 9001) is highly recommended.

- A background in Statistical Analysis or quality control tools is advantageous for data-driven decision-making.

- Experience with quality inspection tools and methodologies is beneficial for the role.

- Minimally, you should have a GCE 'O' Level qualification to qualify for this job role.

-

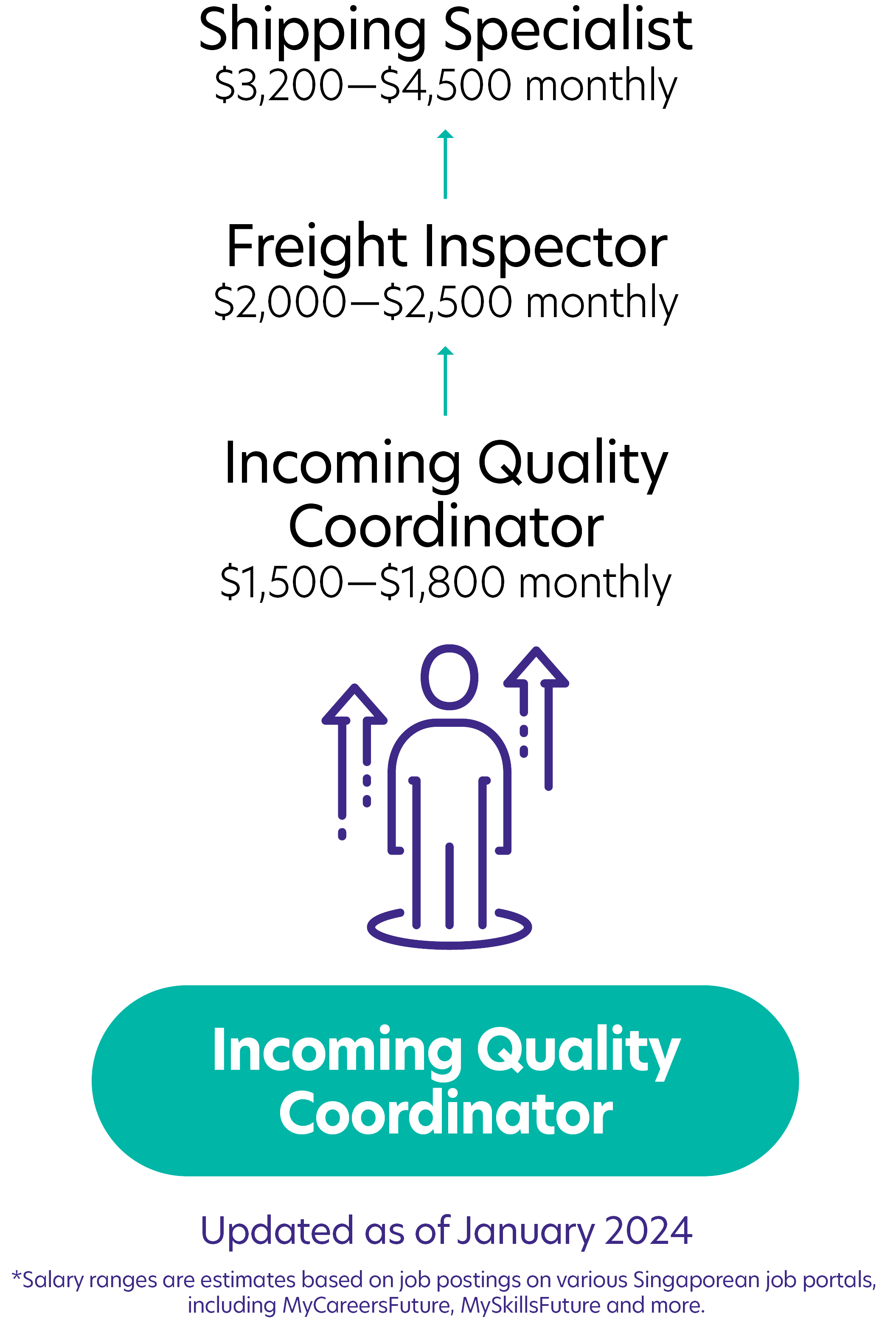

Possible PathwayPossible Pathway

Skills you need to pursue an Incoming Quality Coordinator career in Singapore

Hard Skills

Hard Skills

Basic Computer and Mathematics for Calibration and Specific Measurements

Proficiency in Mathematics is needed for efficiency.Mastery of Measuring Devices Like Gauges, Metres and Computers

Skilled in using multiple tools for accurate assessments.Understanding of Target Market and Consumer Needs

Ability to understand market and consumer demands for better product alignment.Systematic

Has a proven ability to work well with teams to achieve common goals.Observant

Demonstrates skill at finding innovative solutions for complex challenges.Detail-oriented

Meticulous and insightful on specifics to ensure quality.Related Job Roles

Explore Other Programmes

Browse AllYou have bookmarked your first item!

Find it in My Discoveries with insights on your interests!